All product genres

Improved straightening costs for material removal and roughing! Introduction of slicing processing by wire discharge contour machine!!

(1) Purpose In the material removal of high-hardness materials, the blade escaped with the existing band saw and the yield was poor. I was doing slicing with a wire electric discharge machine, but it takes time to process and stagnation occurs in other machinings, so I want to improve the process of material removal. (2) […]

【During the campaign】Drilling and threading are processed simultaneously with one tool! Thread cutting tool "Thread Mill"

What is a thread mill? It is a new threading tool that replaces the "tap" used for normal threading in cutting tools. Drilling and threading can be drilled simultaneously with a single tool, greatly reducing tool change time. ➀ Purpose Solving the problem of tap processing with a thread mill Automation of thread cutting of […]

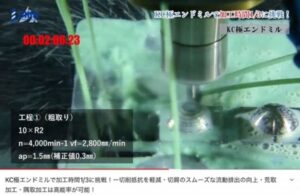

Realized 1/3 of the machining time! Introducing the effect of using KC radius end mill in comparison with carbide ball end mill

➀ Purpose By replacing the "three-dimensional contour line shape processing" that was conventionally performed with a carbide ball end mill with a KC radius end mill and processing it, the "effect obtained" is maximized. (2) Points of introduction ・Significantly shortening of machining time, reduction of the type and number of end mills used, concentration of […]

The effect of 50% reduction in manufacturing costs! Example of introduction of CAM software for automatic generation of processing programs

➀ Purpose Daytime time is taken up to create a machining program, and the operation rate of machining at the machining center decreases. It takes time to train NC program mers, but there is a problem that we want to reduce the time required to create machining programs and increase the utilization rate of machining […]

20% cost reduction!! Introducing a case study of graphite processing with Nikko Equipment's original diamond coating end mill!!

➀ Purpose Using tools from domestic manufacturers, they were processing graphite, which is a brittle material, but they were struggling to maintain machining accuracy and surface quality due to the occurrence of wear and chipping. In order to stabilize the quality, the number of tool changes increased, which was costly. By selecting tools with excellent […]

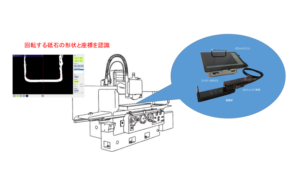

"Shortening Grinding Processing Time on the Order of Microns with a New Method: Rotating Grinding Wheel Measuring Camera System"

➀ Purpose Due to the influence of the shape of the grinding wheel and the runout of the grinding wheel shaft in precise grinding processing, there was a problem that it was necessary to repeatedly check the shape of the grinding wheel by discarded research (dummy machining) and check the workpiece after grinding processing in […]

Mold-based roughing processing Achieved processing efficiency 2.8 times!!

➀ Purpose Increased efficiency and cost reduction of mold-based roughing operations (2) Points of introduction The Φ16 high-feed cutter made by another company that had been used in the past was switched to the TD4N made by MOLDINO. Shortened machining time by greatly increasing processing efficiency and cost reduction by improving the durability of inserts. […]