➀ Purpose

Due to the influence of the shape of the grinding wheel and the runout of the grinding wheel shaft in precise grinding processing, there was a problem that it was necessary to repeatedly check the shape of the grinding wheel by discarded research (dummy machining) and check the workpiece after grinding processing in processing with severe dimensional tolerances. By making it possible to check the exact shape of the grinding wheel (including the runout width of the grinding wheel during rotation) on the machine, we would like to shorten the processing time and improve the processing accuracy.

(2) Points of introduction

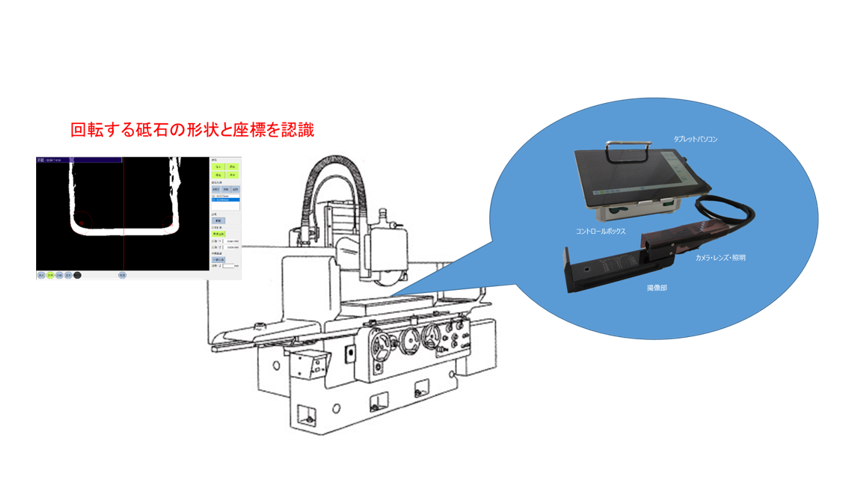

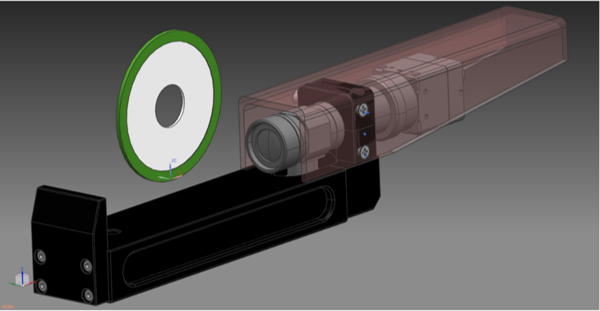

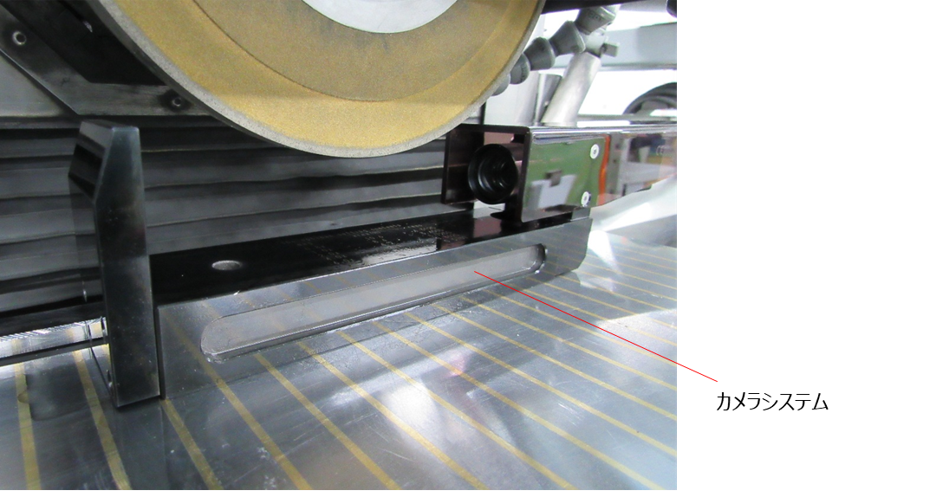

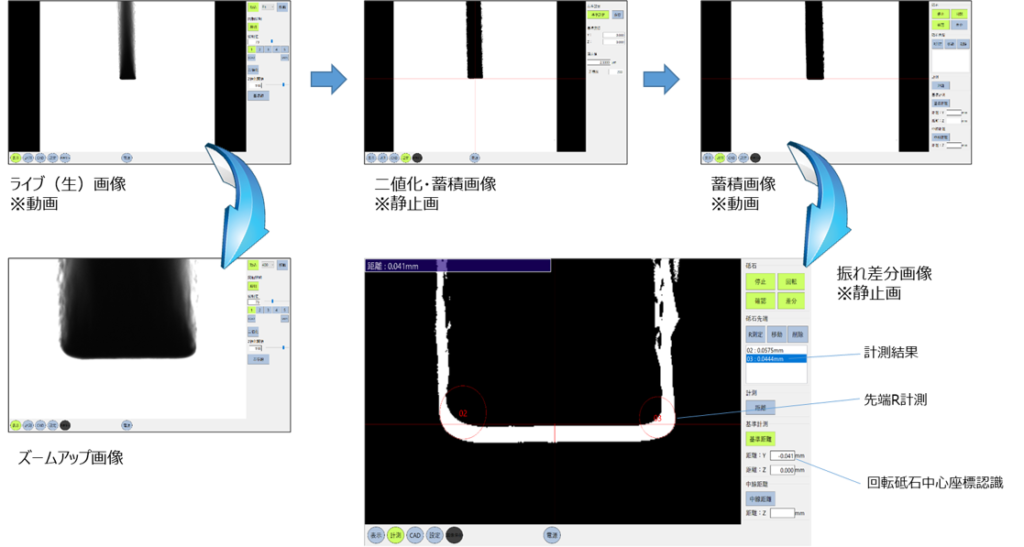

・Optimize the camera system and application of the on-board measuring machine NK-2000 for rotating wheel measurement and grasp the shape of the end face of the whetstone by special optical system configuration.

・ Confirm the shape of the grinding wheel at the time of processing by accumulating images of the runout of the high-rotating whetstone and transferring it to the workpiece.

・Visualization of micron-order positioning on the grinding machine is realized.

(3) Examples

・Operation method

By pressing the image capture button of the whetstone measurement application on the tablet PC while rotating the whetstone, the shape of the rotated whetstone is captured as an accumulation image, and the tip shape of the rotating whetstone is visualized from the accumulated data.

(4) Results

・I was surprised that it became possible to check the shape of the whetstone that rotates so far on the aircraft.

・ Discarding labs (dummy processing) to check the shape of the whetstone are no longer necessary, and the processing time can be reduced.

・By checking the shape of the grinding wheel before processing, it was possible to reduce the cause of the shape (dimension) defect after processing.