Machines

Improved straightening costs for material removal and roughing! Introduction of slicing processing by wire discharge contour machine!!

(1) Purpose In the material removal of high-hardness materials, the blade escaped with the existing band saw and the yield was poor. I was doing slicing with a wire electric discharge machine, but it takes time to process and stagnation occurs in other machinings, so I want to improve the process of material removal. (2) […]

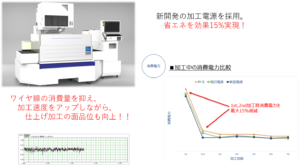

Achieves both a maximum 15% reduction in power consumption during machining and high-precision machining! Western Electric wire electric discharge machine adopting a new power supply!!

(1) Purpose Expectations are rising for energy-saving and highly functional machines. Western Electric's wire electric discharge machine adopts a newly developed processing power supply. While realizing energy saving, we will introduce the effects of shortening cycle time, improving quality, and low running costs. (2) Points of introduction 1.Realize energy saving compared to current power sources2.Reduce […]

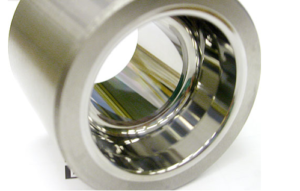

Lead time reduced by 93%! Introduction of the hybrid method of cutting + grinding!

(1) Purpose In the production of a general cold forging mold, the shape is formed using the pattern carving electric discharge machine, and the machined surface is finished by hand. By performing rough processing and finishing processing with one SFG series unit, we will introduce a processing method that shortens the lead time of mold […]

Shortened lead time by processing after heat treatment!

(1) Purpose By performing roughing and tap processing after heat treatment, we introduce a processing method that shortens the lead time of mold manufacturing. (2) Points of introduction Highly versatile ultra-precision micro processing machine Precision micro processing machine that can also use the "Vision" Φ16 end mill made by Sora Sangyo and can perform heavy […]

Yongsing Techno Co., Ltd.

Introduced sludge recovery equipment to improve the facility environment and quality. Purpose Challenges The bad odor of the coolant liquid of the machining center and sludge causing adverse effects on workpieces, machines, and tools. Points of introduction Anyone can operate it. Easy to operate. The machining center can be operated while working. Easy to maintain. […]