Proposal of optimal tools to solve problems at work sites

As "the only partner in Japan that can contribute to the interests of our customers", we propose optimal tools to solve all kinds of problems such as efficiency improvement, high-hardness material processing, cost reduction, etc. at the manufacturing site of mold and parts manufacturers.

KC Polar End Mill

Developed a radius end mill based on low-rotation and high-feed processing technology.

Realized a 30% increase in processing efficiency!

Compatible with hardened materials.

- Adopted a 3D negative-shaped blade shape suitable for low-speed high-feed processing.

- Reduces the occurrence of vibration by suppressing the impact during processing.

- Increasing the width of the cutting process so that the protrusion length can be extended.

- Realizing a long service life with high hardness materials by suppressing the generation of heat during processing .

- Compatible with the processing of 60HRC high hardness materials.

JIMK NK End Mill

"The cheapest place in Japan" High-performance carbleed end mill

It is ideal for processing non-ferrous such as aluminum and copper, carbon steel, pre-hardened steel, and high-hardness materials of HRC48 or less. There is also a lineup of ball end mills that can handle the processing of high-hardness materials of HRC50 or more.

- Surprising low price setting.

- We can also manufacture sizes that are not in the ready-made lineup.

- TiAln coating for processing a wide range of hardness workpieces.

- Original coatings for hardened materials.

MOLDINO PN Coated End Mill

Joint development with MOLDINO!

Realize the low price!

It is a PN-coated carbide end mill with excellent welding resistance and ideal for processing mold materials, high-hardness materials, and parts of HRC50 or less.

- Low weldability, and can be used for processing aluminum, copper, and resin.

- Excellent sharpness due to the adoption of the original position blade type.

- Versatile two-blade, four-blade square-end mill.

- Low price while made by MOLDIN.

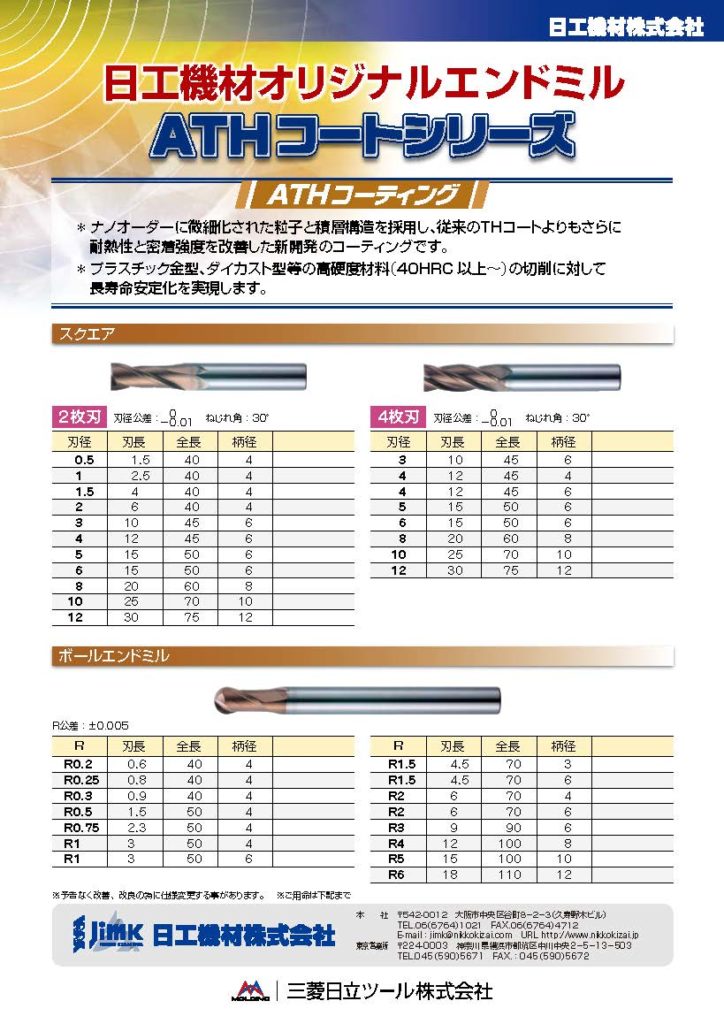

MOLDINO ATH Coat End Mill

Joint development with MOLDINO!

Realize the low price!

This is an ATH-coated carbed end mill that can process high-hardness materials from pre-hardened steel to HRC60.

- Can be used for the processing of a wide range of workpieces, from pre-hardened steel (HRC40 or more) for plastic molds to SKD11 types of pressed mold materials with high hardness.

- Excellent sharpness due to the adoption of the original position blade type.

- Versatile two-blade, four-blade square-end mill.

- Low price while made by MOLDINO.

MOLDINO SD Coated End Mill

Hydrogen-free DLC coating as close as possible to diamonds

Hydrogen-free DLC coating (hardness: 60Gpa or more), which is as close as possible to diamond, is effective for cutting aluminum alloys, resins, and copper, and generates little heat and is ideal for dry cutting.

- The extremely smooth DLC coating has few impurities and is highly heat-resistant and enables high-efficiency processing. Maintains high hardness even at heat-resistant temperatures of 600°C and atmospheric temperatures of 600°C!

- Sharp cutting edge prevents chips from welding (coefficient of friction: 0.1 or less) and achieves a high-quality finishing surface.

- Compatible with high-efficiency cutting processing more than 10 times compared to uncoated carbide!

MOLDINO PN Coat Mills

The ultimate collaboration between the ultra-efficient end mill "Epoch Mills" and the ultra-lubricated "Panasia Coating"

- Time-reduced by high cut.

- Panasia coating for a variety of materials.

- The tool aggregation of the later process can be reduced, and the tool cost is reduced!

- Stable processing with reduced vibration is possible!

仕様

- Moldino

- Carbilled end mill

- 4 blades

- 2 types available (regular type, 3Dc type under the neck)

-Regular type: 5 sizes up to Φ6 ~ Φ16 - 3 DC type under the neck

-4 sizes up to Φ6 ~ Φ12 - Wave blade type

- Blade diameter tolerance: 0 to -0.05

MOLDINO Epoch D Thread Mill 3D

MOLDINO Co., Ltd. Co-developed with Jimk Original Epoch D Thread Mill 3D Type TH Coating MOLDINO! The thread mill of the neck length 3D type of the japanese engineering equipment original is newly introduced! In addition, it is versatile!

With this one piece, drilling holes into high-hardness materials + threading can be performed simultaneously. No bottom hole needed! In addition, the high-strength blade design reduces edge damage in harsh machining environments with hardened materials!

- From M3 to M12, 7 sizes are available.

- Handle a wide range of tools.

- Screw machining, from cast iron to high-hardness materials.

Epoch Epoch is a registered trademark of MOLDINO Co., Ltd.

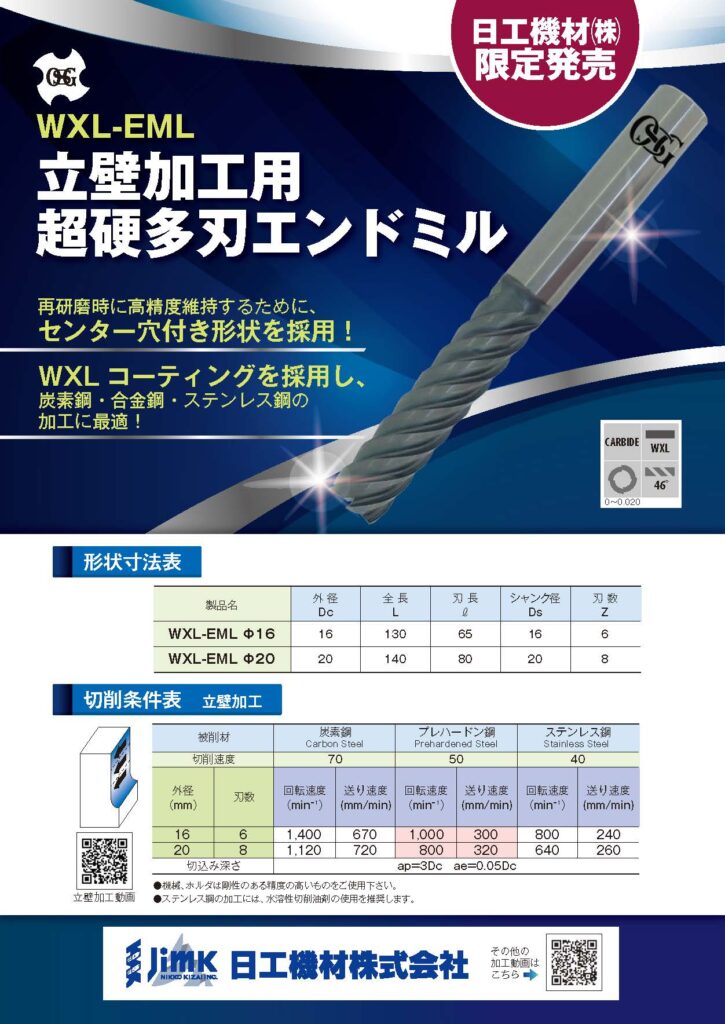

OSG WXL-EML

Co-development of Aussie&Y&A equipment! Ultra-hard multi-blade end mill for standing wall processing WXL-EML

- WXL coating makes it ideal for processing carbon steel, alloy steel and stainless steel

- High helical, multi-blade to ensure thick core thickness

- In the finishing process of a high standing wall, the escape and bibiri of the end mill are suppressed.

- High-precision reg polishing by adopting center-holed shape

仕様

- OSG

- 46-degree twist

- Blade diameter tolerance:

- Ultrafine-particle carbic alloy

- WXL coating

OSG PHX-LN-DBT

Jointly developed with OSG.

A high-efficiency small-diameter long-neck ball end mill that supports low rotation and high feed processing.

By adopting WXS coat, it is also possible to process high-hardness materials up to HRC60.

- High rigidity with a short blade length of 0.75D. Cutting standing walls with low resistance.

- The accuracy of standing walls is improved by scrapnel processing using outer peripheral blades.

- The slim shape of the neck is effective for 5-axis machining with a short neck length.

- Compatible with processing of 60HRC high-hardness materials.

- For high-efficiency processing with hardness materials.

Tap Shots

A dedicated simple electric discharge machine to remove broken taps and drills!

It can be easily set to a processing machine or workpiece with a magnet, and you can choose where to work.

- Significantly shorter working time than shape-carved electric discharge machine (in the case of M6 tap, it can be removed in about 5 minutes)

- Easy to use

- 100V power supply

- Energy-saving design

NIKKO KIZAI INC. Page on Alibaba

Together with mold maker

To make people enrich through our brand powe with tradition and innobation.