Improved straightening costs for material removal and roughing! Introduction of slicing processing by wire discharge contour machine!!

(1) Purpose

In the material removal of high-hardness materials, the blade escaped with the existing band saw and the yield was poor. I was doing slicing with a wire electric discharge machine, but it takes time to process and stagnation occurs in other machinings, so I want to improve the process of material removal.

(2) Points of introduction

・ Adopted

Tinatech wire discharge precision contour machine ・ High versatility

that can be processed if it is a conductive material as well as processing of difficult-to-cut materials with high hardness for electric discharge machining ・ Yield can

be improved because 0.18 Φ ~ 0.2 Φ wire can be used ・ The machining speed is faster

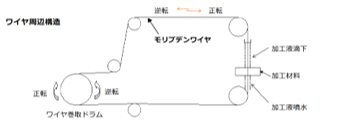

than a wire electric discharge machine that uses brass wire because it uses molybdenum wire ・ Molybdenum wire is wrapped around the drum at the rear of the machine and repeated forward and reversed to enable long-term correspondence, so that the lanning cost can be reduced.

(3) Examples

Processing contents: Disc slice processing

Type: DKS7725-I

Material: Titanium Φ170mm

Processing time of < cost-effectiveness estimation >

slicing processing (1 sheet): 4 hours

wire ¥32/hours,

processing liquid ¥40/hours,

filter¥22/hours, guide, ¥75/hours,

electric power: ¥44/hours, (depending on electricity unit price)

Total ¥213/hours,

⇒4 hours, ¥852

(3) Results

・Since molybdenum wire can be used repeatedly by retrospective reversal, the consumption according to the manufacturer's calculation was about 128 yen.

・ Since ion exchange resin is not used, it was very good that it could operate without running cost as much as possible.

・Compared to conventional electric discharge machines, the machining speed was achieved.

・Compared to the band saw, it is safer and yields are better.