I want to reduce electric discharge machining

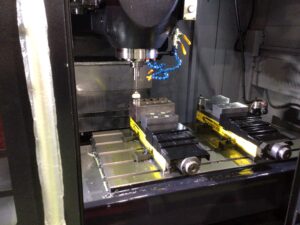

Improved straightening costs for material removal and roughing! Introduction of slicing processing by wire discharge contour machine!!

(1) Purpose In the material removal of high-hardness materials, the blade escaped with the existing band saw and the yield was poor. I was doing slicing with a wire electric discharge machine, but it takes time to process and stagnation occurs in other machinings, so I want to improve the process of material removal. (2) […]

Reduced work time from 40 minutes to 2 minutes! High-efficiency, high-precision drilling of high-hardness steel

(1) Purpose Process in drilling of high-hardness steel, shortening of processing time (2) Points of introduction It is a tool with high rigidity and cutting edge strength suitable for high-hardness steel, and a special groove shape that enhances chip discharge, and shortens the time to use in non-step processing after quenching. Reamerless processing is possible, […]

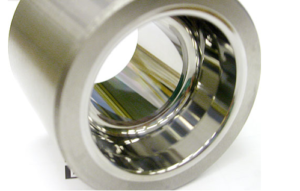

Lead time reduced by 93%! Introduction of the hybrid method of cutting + grinding!

(1) Purpose In the production of a general cold forging mold, the shape is formed using the pattern carving electric discharge machine, and the machined surface is finished by hand. By performing rough processing and finishing processing with one SFG series unit, we will introduce a processing method that shortens the lead time of mold […]