I want to keep running costs down

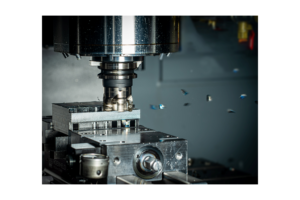

The effect of 50% reduction in manufacturing costs! Example of introduction of CAM software for automatic generation of processing programs

➀ Purpose Daytime time is taken up to create a machining program, and the operation rate of machining at the machining center decreases. It takes time to train NC program mers, but there is a problem that we want to reduce the time required to create machining programs and increase the utilization rate of machining […]

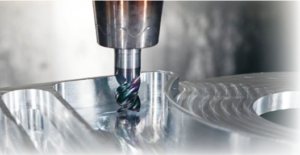

20% cost reduction!! Introducing a case study of graphite processing with Nikko Equipment's original diamond coating end mill!!

➀ Purpose Using tools from domestic manufacturers, they were processing graphite, which is a brittle material, but they were struggling to maintain machining accuracy and surface quality due to the occurrence of wear and chipping. In order to stabilize the quality, the number of tool changes increased, which was costly. By selecting tools with excellent […]

Mold-based roughing processing Achieved processing efficiency 2.8 times!!

➀ Purpose Increased efficiency and cost reduction of mold-based roughing operations (2) Points of introduction The Φ16 high-feed cutter made by another company that had been used in the past was switched to the TD4N made by MOLDINO. Shortened machining time by greatly increasing processing efficiency and cost reduction by improving the durability of inserts. […]

Aluminum grooving reduces machining time at twice the feed rate

➀ Purpose Reduction of processes and machining times in aluminum grooving (2) Points of introduction DLC coating, which demonstrates its power against non-ferrous metals such as aluminum alloys that require weld resistance and lubricity, improves durability and shortens processing time by increasing feed rates. Comparison of feed rates of various companies (3) Processing verification Machining […]

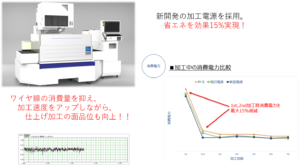

Achieves both a maximum 15% reduction in power consumption during machining and high-precision machining! Western Electric wire electric discharge machine adopting a new power supply!!

(1) Purpose Expectations are rising for energy-saving and highly functional machines. Western Electric's wire electric discharge machine adopts a newly developed processing power supply. While realizing energy saving, we will introduce the effects of shortening cycle time, improving quality, and low running costs. (2) Points of introduction 1.Realize energy saving compared to current power sources2.Reduce […]

MOLDINO Co., Ltd.

Introduction of SUS Multi Reduces Monthly Processing Costs by 60% Purpose Challenges We received a consultation about wanting to shorten the current 90 minutes machining time for processing SUS304. Points of introduction We have proposed EPSM for SUS special tools. Bibrating inhibition blade type unequal division shape, Smooth chip discharge with two-stage gash Double Exen […]