➀ Purpose

Daytime time is taken up to create a machining program, and the operation rate of machining at the machining center decreases. It takes time to train NC program mers, but there is a problem that we want to reduce the time required to create machining programs and increase the utilization rate of machining centers.

(2) Points of introduction

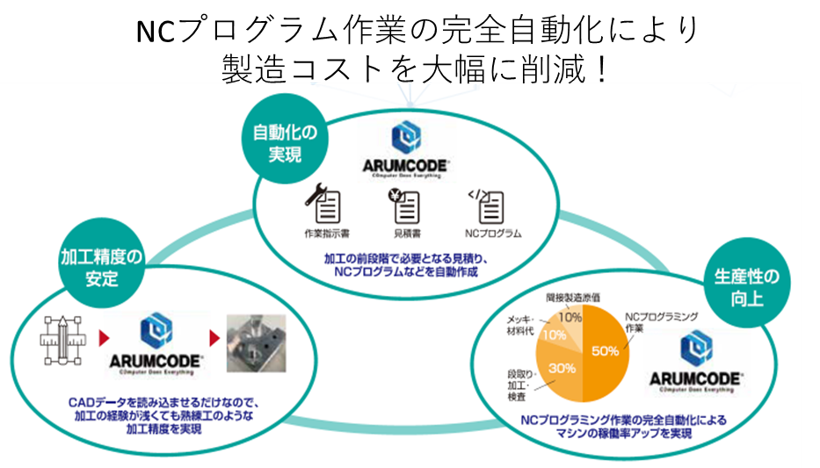

・ ARUMCODE manufactured by ALM Co., Ltd. automatically generates

NC programs simply by reading CAD data ・ AI software

based on the concept of fully automatic ・ While reducing the load on NC program creators, You can increase the operation rate of the machining center

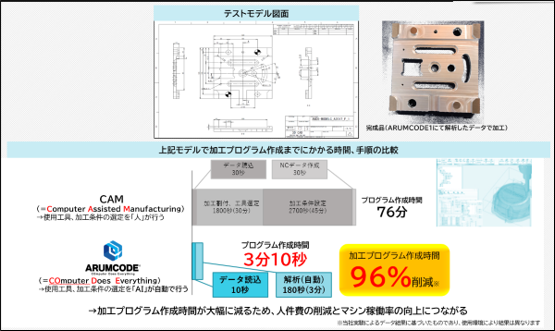

(3) Examples

* It is based on the data results of the ALM experiment, and the results vary depending on the usage environment.

Soft < Specifications>

/ Machineable models : Vertical 3-axis machining center

/ Compatible NC control : FANUC, Mitsubishi Electric (Merdas)

/ Workpiece to be machined : 6F material

/ Recommended workpiece size: 200 mm × 200 mm × 50 mm

/ Number of tools that can be registered: 1,000 pieces

/ Workpiece fixing method: Vice

/ CAD data format: STL

(4) Results

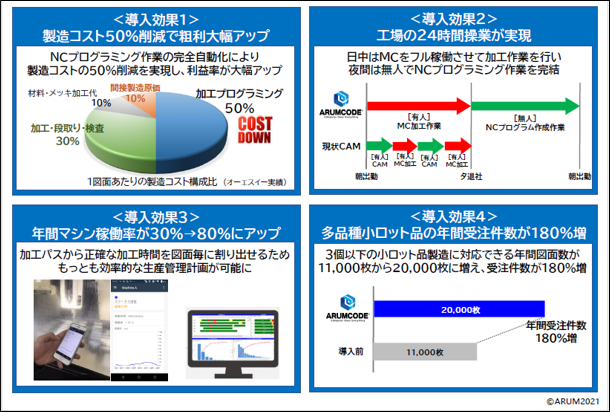

・The time required to create a processing program was reduced by 96% compared to the current CAM.

(The number of drawings per year increased

from 11,000 to 20,000)

・ NC programming work can be completed unmanned at night, and it has become possible to fully operate the machining center during the day.

(Annual machine utilization rate increased by 30% →80%) ・Efficient production management planning became possible, and the number of orders received annually for high-mix small-lot products increased

by 180%.

(5) ARUMCODE will continue to evolve in the future

* ALM Group companies: Effect of test introduction at OSE Co., Ltd.

< future update planned>

latest version upgrade (scheduled for June)

ARUMCODE1 ver.2

→ 2.5-axis machining→ program

generation

taking into account tool correction→ further improvement of tool running path

ARUMCODE2: Compatible with Lathe MachiningARUMCODE3: Compatible with Polishing ARUMCODE4: Compatible with

Castings Processing

And so on, many additional functions!!