Reduced machining time by 67%! Introducing a case study of high-efficiency processing using KC polar end mills!!

(1) Purpose

In order to improve machining efficiency using the machining center we have, we utilize a new tool "KC Polar End Mill" based on new processing technology.

(2) Points of introduction

- New three-bladed radius end mill based on low speed high feed processing technology

- Special 3D negative shape with 3 blades reduces vibrating and heat generation

- Adopting a pocket shape with high discharge of chips

⇒ high-efficiency processing is possible by roughing, medium finishing, and finishing processing.

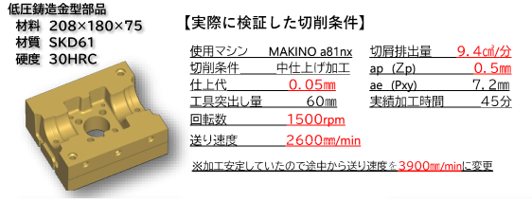

(3) Processing details

(4) Processing results

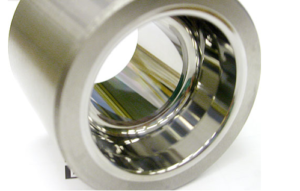

●Workpiece photo after processing

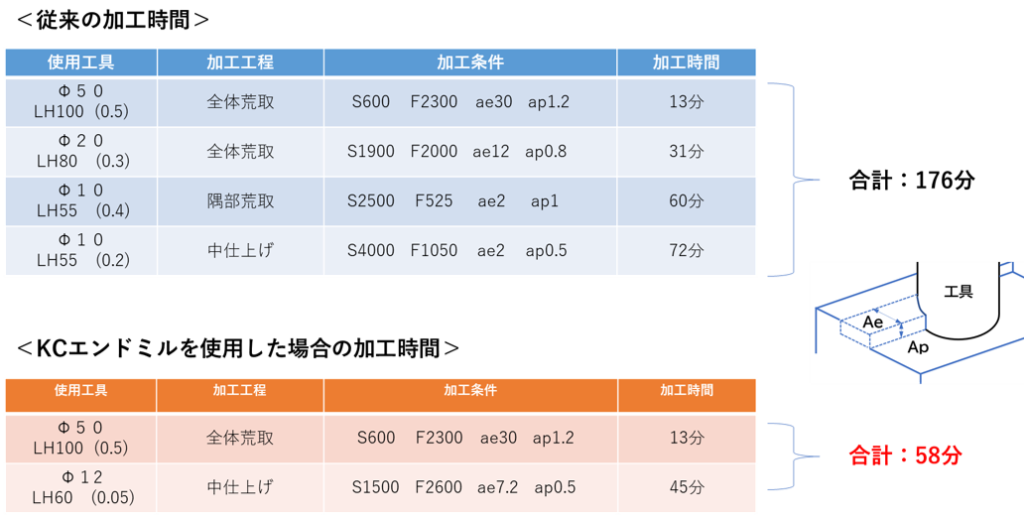

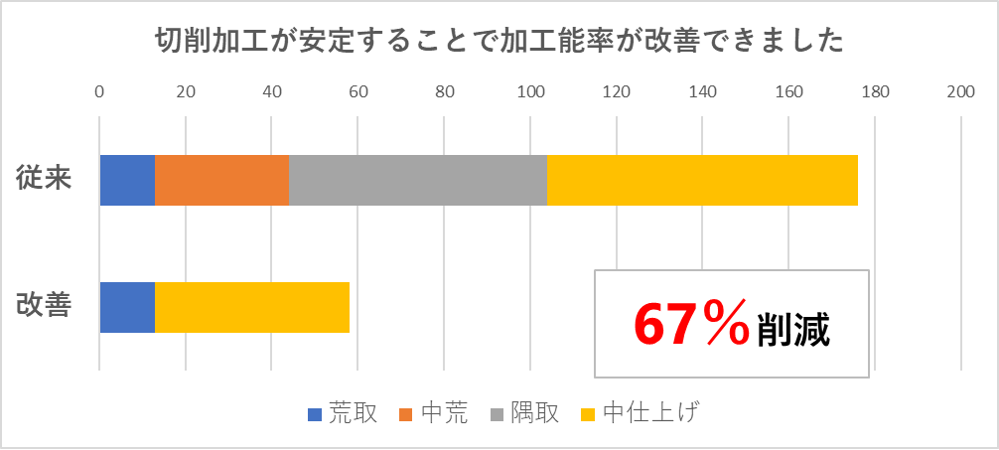

●Comparison of processing times

Since it is possible to reduce vibration by machining at low speeds, we were able to reduce machining time by about 67% compared to conventional tools.

In addition, since the vibration and heat generation were suppressed, we were able to perform processing without tool wear.