(1) Purpose

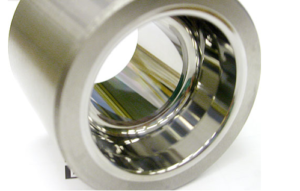

In the product section of injection molding molds, it took a lot of time to process the machined surface (hand polishing) after

cutting, discharging, and grinding processing.

Low pressure shot blasting is used for

process improvement with fine shapes and many polishing points, making it difficult to improve efficiency.

(2) Points of introduction

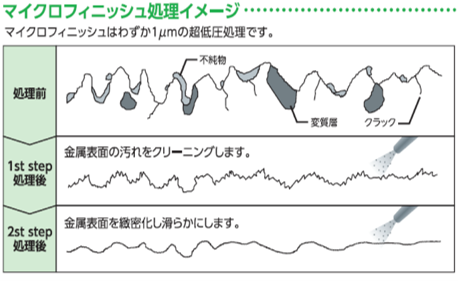

Sablux ultra-low pressure shot blast "Unifinish"

(1) Pressure adjustment from 0.03MPa is possible

(2) Use

of original grinding materials with a minimum granular shape of 7μ (3) Surface treatment without dripping on the edge part is possible

(3) Details of introduction

Processing with Unifinish "UNF-55 COMBO"

Blasting is performed on workpieces that used to take two hours to polish by hand.

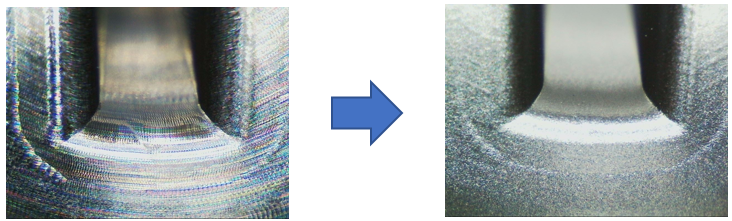

Since we were particularly struggling to process the boundary between the bottom of the product and the shape part,

that part became an evaluation point.

(4) Results of introduction

・In hand polishing, it was possible to process the part that took 2 hours in about 3 minutes by

blasting in 2 stages.

・ Even difficult parts by hand polishing evaluation points were sufficiently processed.

・Although it depends on the molding material, the releasability during injection molding has been improved by the surface after treatment.