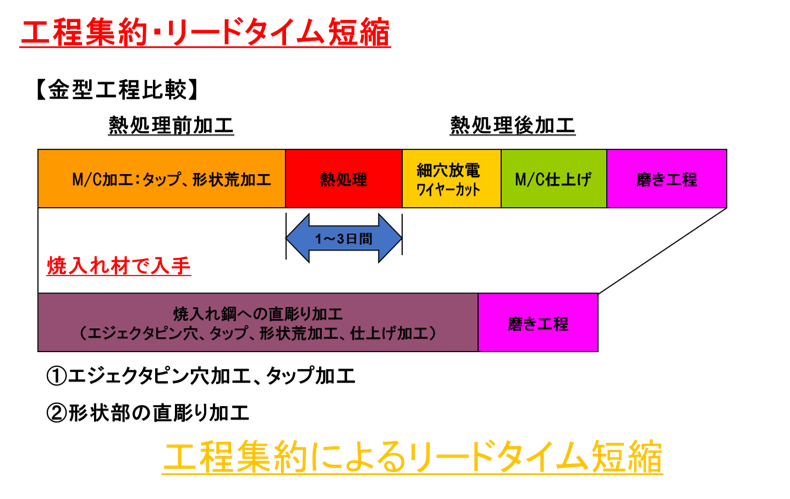

(1) Purpose

By performing roughing and tap processing after heat treatment,

we introduce a processing method that shortens the lead time of mold manufacturing.

(2) Points of introduction

- Highly versatile ultra-precision micro processing machine Precision micro processing machine that can also use the "Vision"

Φ16 end mill made by Sora Sangyo and can perform heavy cutting - Use of CAM dedicated to rough processing developed independently by Rice Industries

- Use of TH3 coating tools from MOLDINO suitable for high-hardness materials

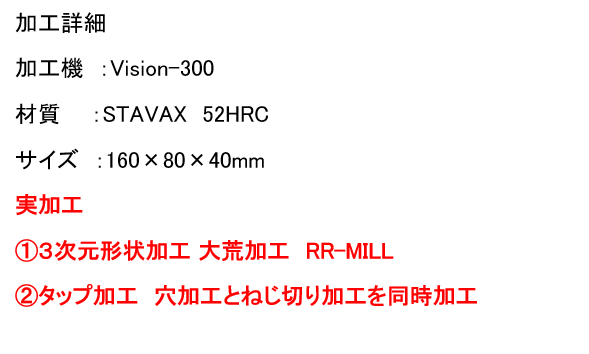

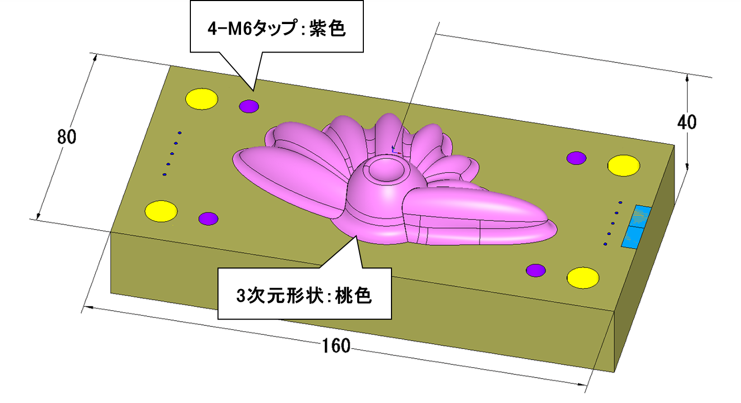

(3) Processing details

(4) Processing results

Processing result (1) Three-dimensional shape roughing

Point

(1) High-efficiency roughing

with a high-precision processing machine Reduction of ⇒ "crossing machining"

(2) Dedicated processing machine CAM RR-Mil

⇒ machining so that it runs up from the bottom to the top

⇒ Effective use of the tool side and shortening the cutting length ⇒

Cycle time and tool life extension are both

achieved (3) Optimal tool Use

of EHHBE made in Mordino ⇒ High R-shape accuracy due to the escape angle shape of special four-bladed blades ⇒

vibration suppression effect due to unfair division

Processing result (2) M6 tap

Point

(1) Use

of epoch D thread mill⇒ reduction

of machining time by bottom hole + thread cutting with one tool ⇒ easy to program with dedicated software ⇒

smooth discharge of chips by special design cutting edge and stopper shape

By

performing the effect roughing and tap processing before quenching, the heat treatment process occurs,

and the number of processes increases because the roughing machine and the finishing machine are separated

. Processing

is performed after heat treatment, and the reduction of "watari machining" due to

roughing with high-precision processing machines leads to a shortening

of the lead time of the mold manufacturing process.