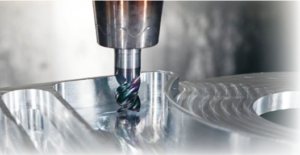

(1) Purpose

When machining with a long machining time, the coolant becomes insufficient, and an alarm is issued and the machine stops. The task of adding to the patch became laborious, and it was a state where people had to get it.

(2) Points of introduction

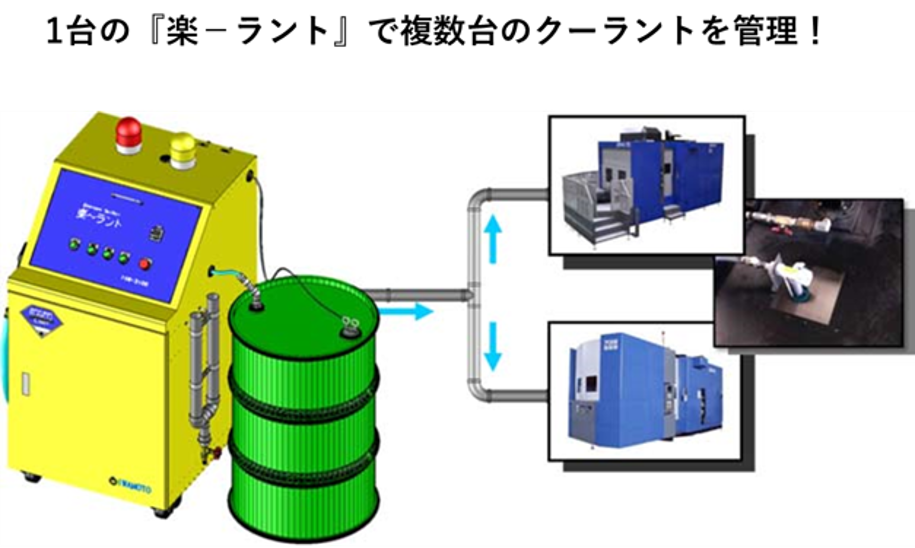

Introduced Iwamoto Kogyo's "Raku~Ranto".

・ By connecting pipes from one easy ~ rant and setting a ball tap on the coolant tank, it is possible to manage the coolant water amount of multiple machine tools.

・At the concentration set at the time of supply from Raku~Land, coolant is automatically filled into the machine tool tank.

・Large-scale electrical work is not required because it can be operated with a 100V power supply.

(3) Examples

■Examples of introduction

Introduced two Raku~Ranto to five machine tools.

The replenishment work of the processing fluid, which had been performed once every two days,

became zero (zero) due to the introduction of an automatic feeding device.

(4) Results

(Testimonials)

・ We no longer have to worry about processing during long holidays when the amount of coolant water is insufficient and processing is stopped.

・Added equipment has been automated, reducing the time required for coolant management.