➀ Purpose

Reduction of processes and machining times in aluminum grooving

(2) Points of introduction

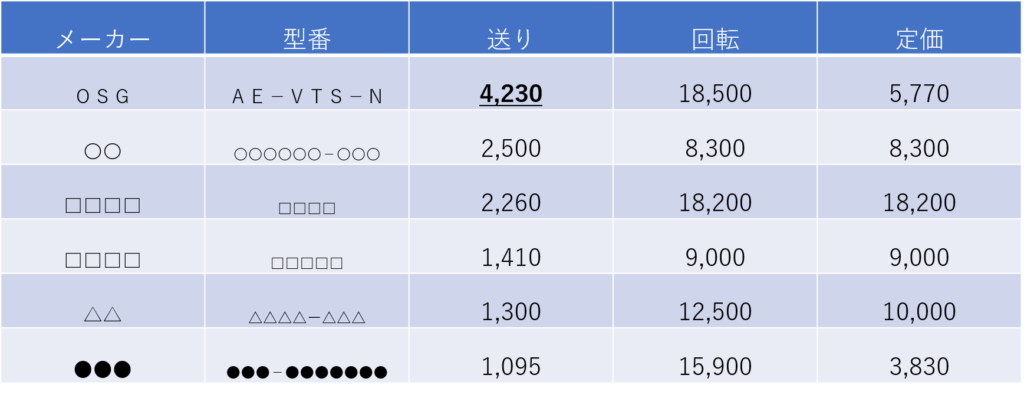

DLC coating, which demonstrates its power against non-ferrous metals such as aluminum alloys that require weld resistance and lubricity, improves durability and shortens processing time by increasing feed rates.

Comparison of feed rates of various companies

(3) Processing verification

Machining contents: Aluminum alloy φ6 1D grooving

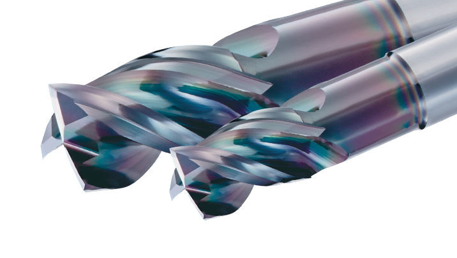

tool used: OSG AE-VTS-N φ6X18

Unequal lead, unequal division blade type without vibrating

(4) Processing results

・ Before introduction, two processes (roughing for roughing, square for finishing) could

be processed in one process ・ The work time was shortened

to about 1/2 by the above introduction ・ The durability of the end mill increased and the number of purchases was

reduced ・ In addition to square, there are variations of pincad and radius and can be used differently by processing