(1) Purpose

Significant waste discharge, long service life, and a finishing cost of 0.1 mm are achieved by one-shot rough processing

(2) Points of introduction

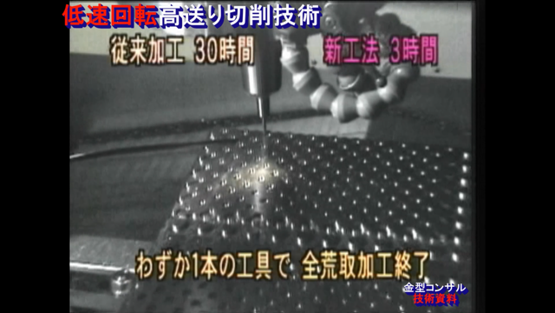

It is a tool developed for low-speed rotation and high-feed machining, and it is a tool that realizes low cutting resistance, reduction of vibration, and high-precision machining during high-hardness materials and deep digging machining. Even if it is not a high-speed rotating MC machine, you can perform highly efficient processing with your own MC machine.

(3) Processing verification

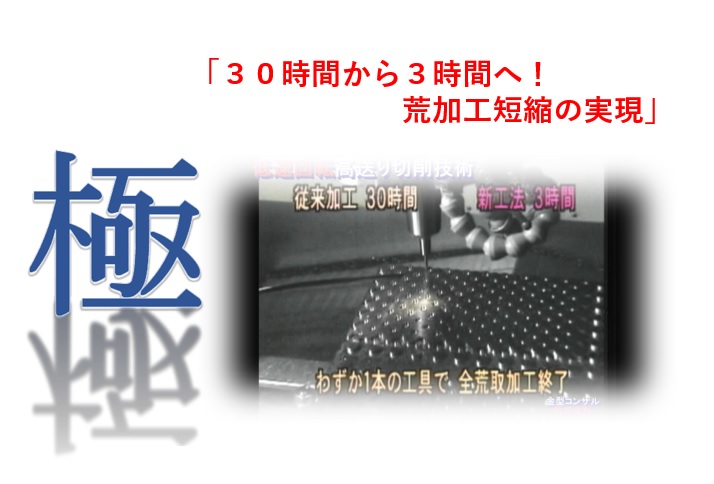

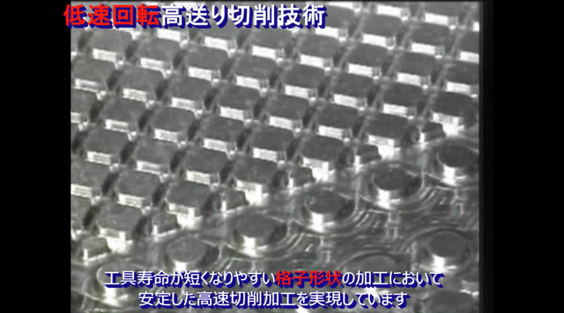

Improvement of lattice shape (improvement of roughing + mid-finish machining)

Current machining time 30 hours Number of tools used 7

⇩

After the improvement, the machining time

is 3 hours, the number of tools used is 1 KC-KMRφ4XR1 (3 blades

) (details of improvement (1) tools, (2) cutting data, (3) data creation method, (4) process assembly method)

(4) Processing results

Voices from users who have verified < >

・ The cutting distance has been extended and the number of tools used has

decreased・ High-efficiency processing has been possible

even if it is not a high-speed MC machine ・ There is no problem with surface quality even if it is used for finishing processing