Search through all challenges

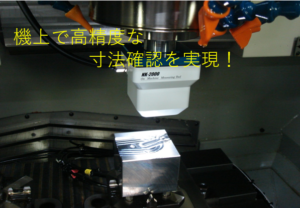

Reduce material loss rates! Introducing the effect of introducing an on-board measuring machine!

(1) Purpose After processing, when measurement is performed using an external measuring machine and additional work is required, it can not be returned to the original posture on the machine table and may be discarded. Using the on-board measuring machine "NK-2000", dimensions are checked on the processing machine, and it is introduced to solve the […]

Reduced machining time by 67%! Introducing a case study of high-efficiency processing using KC polar end mills!!

(1) Purpose In order to improve machining efficiency using the machining center we have, we utilize a new tool "KC Polar End Mill" based on new processing technology. (2) Points of introduction New three-bladed radius end mill based on low speed high feed processing technology Special 3D negative shape with 3 blades reduces vibrating and […]

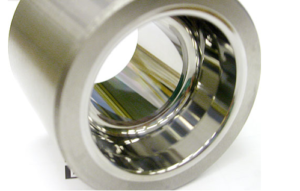

Lead time reduced by 93%! Introduction of the hybrid method of cutting + grinding!

(1) Purpose In the production of a general cold forging mold, the shape is formed using the pattern carving electric discharge machine, and the machined surface is finished by hand. By performing rough processing and finishing processing with one SFG series unit, we will introduce a processing method that shortens the lead time of mold […]

Ultra-low pressure shot blasting technology reduces polish time by about 98%!

(1) Purpose In the product section of injection molding molds, it took a lot of time to process the machined surface (hand polishing) after cutting, discharging, and grinding processing. Low pressure shot blasting is used for process improvement with fine shapes and many polishing points, making it difficult to improve efficiency. (2) Points of introduction […]

Shortened lead time by processing after heat treatment!

(1) Purpose By performing roughing and tap processing after heat treatment, we introduce a processing method that shortens the lead time of mold manufacturing. (2) Points of introduction Highly versatile ultra-precision micro processing machine Precision micro processing machine that can also use the "Vision" Φ16 end mill made by Sora Sangyo and can perform heavy […]

MOLDINO Co., Ltd.

Introduction of SUS Multi Reduces Monthly Processing Costs by 60% Purpose Challenges We received a consultation about wanting to shorten the current 90 minutes machining time for processing SUS304. Points of introduction We have proposed EPSM for SUS special tools. Bibrating inhibition blade type unequal division shape, Smooth chip discharge with two-stage gash Double Exen […]

Yongsing Techno Co., Ltd.

Introduced sludge recovery equipment to improve the facility environment and quality. Purpose Challenges The bad odor of the coolant liquid of the machining center and sludge causing adverse effects on workpieces, machines, and tools. Points of introduction Anyone can operate it. Easy to operate. The machining center can be operated while working. Easy to maintain. […]